OUR PROFILES ARE MUCH MORE THAN SPECIAL

Sipa Spa is specialized in the production of special cold-drawn profiles that are custom designed. It complies thoroughly with all supply requests and specifications, in terms of size, mechanical performance and surface quality.

Steel is by nature an environmentally friendly, recyclable and highly resistant material with excellent mechanical properties. It is processed using cold forming technology which strongly reduces waste and material surplus.

STEELS

| Steel | CORRESPONDENCES | ||||||||

| UNI | EURONORM | DIN | WNr | AFNOR | BS | AISI/SAE | JIS/SUS | ||

CONSTRUCTION STEELS | Non alloyed for structural uses | S235JRG1 | S235JRG1 | S235JRG1 | 1.0036 | S235JRG1 | S235JRG1 | A 570 | STB 35 |

| (Fe 37) | (Fe 37-3 FN) | (St 37-2) | 1.0038 | ||||||

| S275JR | S275JR | S275JR | 1.0044 | S275JR | S275JR | A 510 | SN 400 B | ||

| Fe 42 (Fe410) | (Fe 42-3 FN) | St 42.8 | |||||||

| E295 | E295 | E295 | 1.0572 | E295 | E295 | SS 50 | |||

| (Fe 490) | (St50-2) | ||||||||

| Case hardening | C10 | (C10D) | C10 | 1.0301 | XC10 | En 2 A | 1010 | S 10 C | |

| 1.0310 | |||||||||

| C15 | C15D | C10 | 1.0401 | XC18 | En 32 C | 1015 | S 15 C | ||

| 18CrMo4 | 18CrMo4 | 18CrMo4 | 1.7243 | 18CD4 | 18CrMo4 | ||||

| 16MnCr5 | 16MnCrS | 16MnCrS | 1.7131 | 16MC5 | 16MnCr5 | 5115 | |||

| 16CrNi4 | - | 16NC11 | |||||||

| 16NiCr11 | 14NiCr10 | 1.5732 | 20NCD2 | 3415 | SNC 21 | ||||

| 20NiCrMo2 | 20NiCrMo2-2 | 20NiCrMo2-2 | 1.6523 | 18NCD6 | 805 M 20 | 5333 | SNCM 21 | ||

| 18Cr Ni Mo7-6 | 18Cr Ni Mo7-6 | 1.6587 | 16NCD13 | 18CrNi Mo7-6 | |||||

| 16NiCrMo12-6 | 1.6782 | ||||||||

| X19NiCrMo4 | 1.2764 | ||||||||

| Tempered | C30 | C30 | C30 | 1.0528 | C30 | C30 | 1030 | ||

| C40 | C40 | C40 | 1.0511 | C40 | C40 | 1040 | |||

| C45 | C45 | C45 | 1.0503 | C45 | C45 | 1043 | S 45 C | ||

| C50 | C50 | C50 | 1.0540 | C50 | C50 | 1050 | |||

| C60 | C60 | C60 | 1.0601 | C60 | C60 | 1060 | S 60 CM | ||

| 41Cr4 | 41Cr4 | 41Cr4 | 1.7035 | 42C4 | 530 M 40 | 5140 | SCr 4 | ||

| 25CrMo4 | 25CrMo4 | 25CrMo4 | 1.7218 | 25CD4 | 25CrMo4 | 4130 | SCM 2 | ||

| 42CrMo4 | 42CrMo4 | 42CrMo4 | 1.7225 | 42CrMo4 | 708 M 40 | 4140 | SCM 4 | ||

| 40NiCrMo2 | 40NiCrMo2 KD | 40NiCrMo2-2 | 1.6546 | 40NCD2 | 7 | 8640 | SNCM 6 | ||

| 40NCD16 | |||||||||

| Quenched | C43 | C46 | Cf45 | 1.1193 | S 45 CM | ||||

| C53 | C53 | Cf53 | 1.1213 | XC 48 TS | C53 | S 50 CM | |||

| 41CrMo4 | 41CrMo4 | 41CrMo4 | 1.7223 | 5/1 | 4142 | SNB 22-1 | |||

| 51CrMoV4 | 51CrMoV4 | 51CrMoV4 | 1.7701 | 51CDV4 | - | - | - |

||

| (58CrMoV4) | |||||||||

| For bearings | 100Cr6 | 100Cr6 | 100Cr6 | 1.3505 | 100C6 | 2S. 135 | A29 (A295) | SUJ2 | |

| 100CrMo7 | 100CrMo7 | 100CrMo7 | 1.3537 | 100CD7 | A485 | ||||

| Nitriding | 41CrAIMo7 | 41CrAIMo7 | 41CrAIMo7 | 1.8509 | En 41 B | 6431 | SACM 1 | ||

| For springs | 55Si7 | 55Si7 | 55Si7 | 1.5026 | 55S7 | En 45 A | 9255 | ||

| 50CrV4 | 51CrV4 | 51CrV4 | 1.8159 | 50CV4 | En 47 | 6150 | SUP 10 | ||

| Automatic | CF 9SMn28 | 11SMn30 | 9SMn28 | 1.0715 | S 250 Pb | 230 M 07 | 1213 | SUM 22 | |

| CF 9SMnPb28 | 11SMnPb30 | 9SMnPb28 | 1.0718 | S 250 Pb | 11SMnPb30 | 0 12L13 | SUM 23 L | ||

| For tools | 55WCrV8KU | 55WCrV8 | 60WCrV8 | 1.2550 | |||||

| 90MnCrV8 KU | 90MnCrV8 | 90MnCrV8 | 1.2842 | 90 MV 8 | BO 2 | O 2 | |||

| 107CrV3 KU | 115CrV3 | 115CrV3 | 1.2210 | L 2 | |||||

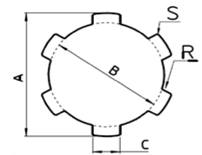

| N° Sipa Profile | N° Splined | Standard sizes | N° Gears | Tolerances | Kg/m | ||||||

| A | B | C | Rmax | Smax | A | B | C | ||||

| 267 | 0 | 14 | 11 | 3 | 0.2 | 0.25 | 6 | -0.07 | -0.03 | +0.00 | 0.95 |

| 187 | 1 | 16 | 13 | 3.5 | 0.2 | 0.25 | 6 | -0.20 | -0.08 | -0.08 | 1.27 |

| 89 | 2 | 20 | 16 | 4 | 0.2 | 0.25 | 6 | 1.93 | |||

| 128 | 3 | 22 | 18 | 5 | 0.2 | 0.2 | 6 | 2.46 | |||

| 21 | 4 | 25 | 21 | 5 | 0.2 | 0.25 | 6 | 3.16 | |||

| 198 | 5 | 25 | 23 | 6 | 0.2 | 0.4 | 6 | 3.97 | |||

| 757 | 6/A | 30 | 26 | 6 | 0.3 | 0.3 | 6 | 4.64 | |||

| 218 | 6/B | 32 | 26 | 6 | 0.3 | 0.3 | 6 | 5.01 | |||

| 767 | 767 | 34 | 28 | 7 | 0.3 | 0.3 | 6 | 5.81 | |||

| 133 | 7 | 38 | 32 | 6 | 0.3 | 0.35 | 8 | 7.39 | |||

| 131 | 8 | 42 | 36 | 7 | 0.3 | 0.3 | 8 | 9.25 | |||

| 184 | 9 | 48 | 42 | 8 | 0.3 | 0.3 | 8 | 12.32 | |||

| 861 | 10 | 54 | 46 | 9 | 0.5 | 0.5 | 8 | 15.20 | |||

| 130 | 1'' 1/8 | 28.52 | 23.65 | 7.03 | 0.3 | 0.3 | 6 | 4.25 | |||

| 20 | 1'' 3/8 | 34.87 | 28.14 | 8.64 | 0.3 | 0.3 | 6 | 6.71 | |||

| 19 | 1'' 3/4 | 44.37 | 36.25 | 11 | 0.3 | 0.5 | 6 | 10.12 | |||

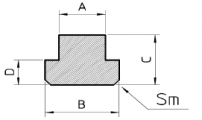

| N° Sipa Profile | Sizes (mm) | Sm 45° | Tolerances (mm) | Kg/m (steel UNI C45) |

||||||

| A | B | C | D | A | B | C | D | |||

| 819 | 5,7 | 10 | 8 | 4 | 1.6 | -0.00 | +0.00 | +0.20 | +0.00 | 0.482 |

| -0.15 | -0.50 | -0.20 | -0.5 | |||||||

| 820 | 8 | 13 | 10 | 6 | 1.6 | -0.30 | +0.00 | +0.20 | +0.00 | 0.845 |

| -0.50 | -0.50 | -0.20 | -0.50 | |||||||

| 796 | 9.7 | 15 | 12 | 6 | 1.6 | -0.00 | +0.00 | +0.20 | +0.00 | 1.150 |

| -0.20 | -0.50 | -0.20 | -0.50 | |||||||

| 821 | 12 | 18 | 14 | 7 | 2.5 | -0.30 | +0.00 | +0.20 | +0.00 | 1.600 |

| -0.55 | -0.50 | -0.20 | -0.50 | |||||||

| 827 | 14 | 22 | 16 | 8 | 2.5 | -0.30 | +0.00 | +0.20 | +0.00 | 2.200 |

| -0.55 | -0.45 | -0.20 | -0.50 | |||||||

| 135 | 16 | 25 | 18 | 9 | 2.5 | -0.30 | +0.00 | +0.20 | +0.00 | 2.882 |

| -0.60 | -0.50 | -0.20 | -0.50 | |||||||

| 136 | 18 | 28 | 20 | 10 | 2.5 | -0.30 | +0.00 | +0.20 | +0.00 | 3.597 |

| -0.45 | -0.50 | -0.20 | -0.50 | |||||||

| 822 | 20 | 32 | 24 | 12 | 2.5 | -0.30 | +0.00 | +0.20 | +0.00 | 4.882 |

| -0.60 | -0.50 | -0.20 | -0.50 | |||||||

| 823 | 21.5 | 36 | 28 | 14 | 3.0 | +0.15 | +0.00 | +0.00 | +0.00 | 6.250 |

| -0.00 | -0.39 | -0.52 | -0.52 | |||||||

| 824 | 21.6 | 35 | 28 | 14 | 2.5 | +0.00 | +0.00 | +0.20 | +0.00 | 6.170 |

| -0.10 | -0.50 | -0.20 | -0.50 | |||||||

| 912 | 28 | 44 | 836 | 18 | 4.0 | -0.30 | +0.00 | +0.20 | +0.00 | 9.850 |

| -0.60 | -1.00 | -0.20 | -1.00 | |||||||

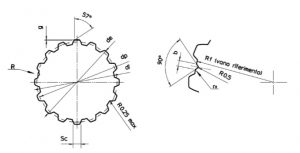

| N° Sipa Prof | N° CUNA | N° gears | Mod. | di | dp | de | Rollers Quote | Rollers Diam. | Rf | Sc | gmax | b | r2 |

| 615 | 25 | 10 | 2.35 | 21.90 | 23.5 | 24.74 | 28.905 | 4.011 sp. 3.3 | 11.55 | 3.620 | 0.15 | 1.2 | 0.75 |

| 21.63 | 24.55 | 28.802 | 11.35 | 3.552 | |||||||||

| 1082 | 30 | 10 | 2.75 | 25.90 | 27.5 | 29.74 | 33.984 | 4.75 sp. 3.75 | 13.55 | 4.240 | 0.15 | 1.5 | 1 |

| 25.63 | 29.55 | 33.882 | 13.35 | 4.172 | |||||||||

| 58- 982 | 35 | 12 | 2.75 | 30.40 | 33.0 | 34.70 | 39.511 | 4.75 sp. 3.75 | 16.15 | 4.245 | 0.15 | 1.5 | 1 |

| 30.03 | 34.45 | 39.407 | 15.85 | 4.177 | |||||||||

| 126 | 40 | 14 | 2.65 | 34.90 | 37.1 | 39.70 | 42.468 | 4.25 sp. 3.50 | 17.90 | 4.091 | 0.20 | 1.5 | 1 |

| 34.56 | 39.45 | 42.359 | 18.20 | 4.023 | |||||||||

| 127- 989 | 45 | 16 | 2.65 | 39.90 | 42.4 | 44.70 | 50.557 | 5.25 | 20.85 | 4.094 | 0.25 | 1.5 | 1 |

| 39.56 | 44.45 | 50.456 | 20.55 | 4.026 | |||||||||

| 1187 | 50 | 18 | 2.65 | 44.90 | 47.7 | 49.65 | 53.806 | 4.50 | 23.10 | 4.100 | 0.25 | 1.5 | 1 |

| 44.56 | 49.40 | 53.698 | 22.80 | 4.032 |

INDICATIVE TOLERANCES FOR SPECIAL PROFILES

BATCH SIZE:

depends on type of steel and shape. Batches between 500 and 1000 Kg upon specific request and under 500 Kg for standard profiles

LOWER TOLERANCE:

minimum tolerance 0.05 mm

ROUGHNESS VALUES:

Ra 1.6 µm minimum

MAXIMUM DIAMETER OF PROFILE OUTSIDE RIM:

Ø 151 mm

MAXIMUM LENGHT OF BARS:

according to customers’ request

MAXIMUM WEIGHT PER METER:

30 Kg/m

MINIMUM RADIUS:

R 0.20

Indicative values. Tolerances lower than the reported values can be agreed upon request.